Range XFE

Download the documentation

Vacuum ovens are required in many processes:

Moderate drying for sensitive products Fast drying Degassing / Degassing of metal Bleeding Heating of metal parts for surface treatment The vacuum avoids oxidation by air Polymerization vacuum -> without oxidation Degassing silicone parts for manufacturers of connectors Sensor of high pressure that must be filled with special oil to protect the sensing element: remove the air from the cavity to fill with oil (vacuum) Test / Calibration of barometers Degassing gel candles to eliminate air bubbles Dehydration of powder solvend soaked

Spacial applications :

When a satellite is launched in space, its components will begin to degas. To avoid problems such as pollution in precision optics in the case of an observation’s satellite, we can force the degassing before the launch by heating under vacuum.

Degassing pieces :

Degassing pieces of high precision for Formula One engine, before surface treatment.

Our Vacuum ovens XFL are suitable for drying* of sensitive products, thermal treatments of oxidizable materials, quick drying of powders and granulate... in pharmaceutical, cosmetics, plastics, electronics, chemical, agrifood… laboratories or industries. * For any drying application, please contact us to explain exactly your need to +33 164213060. We will help you to find the products adapted to your needs. Max temperature :

200°C

Vacuum range : according to your Vacuum pump.

up to 1 mbar

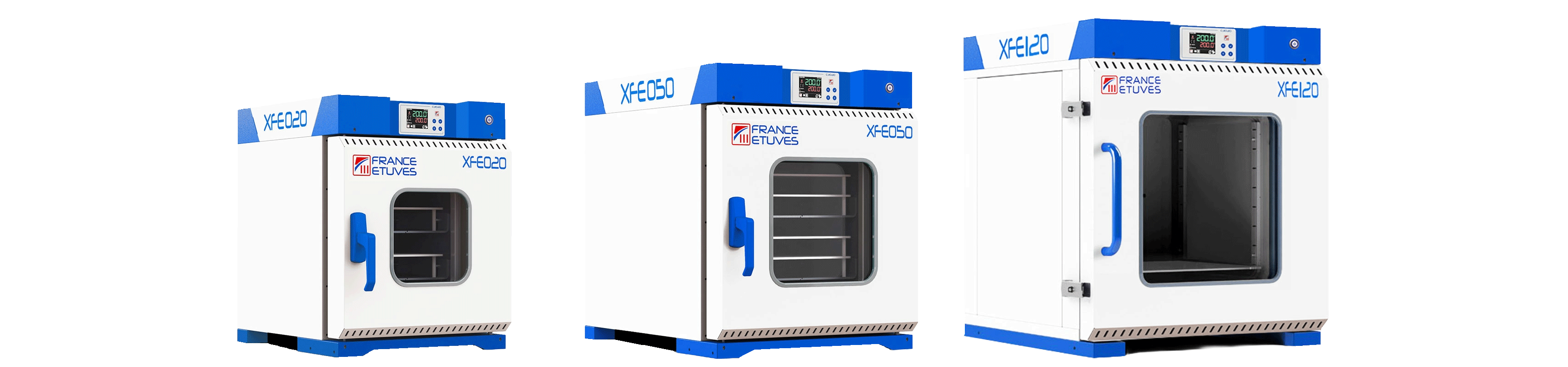

(absolute pressure) 3 sizes : 20, 50 and 120 liters.

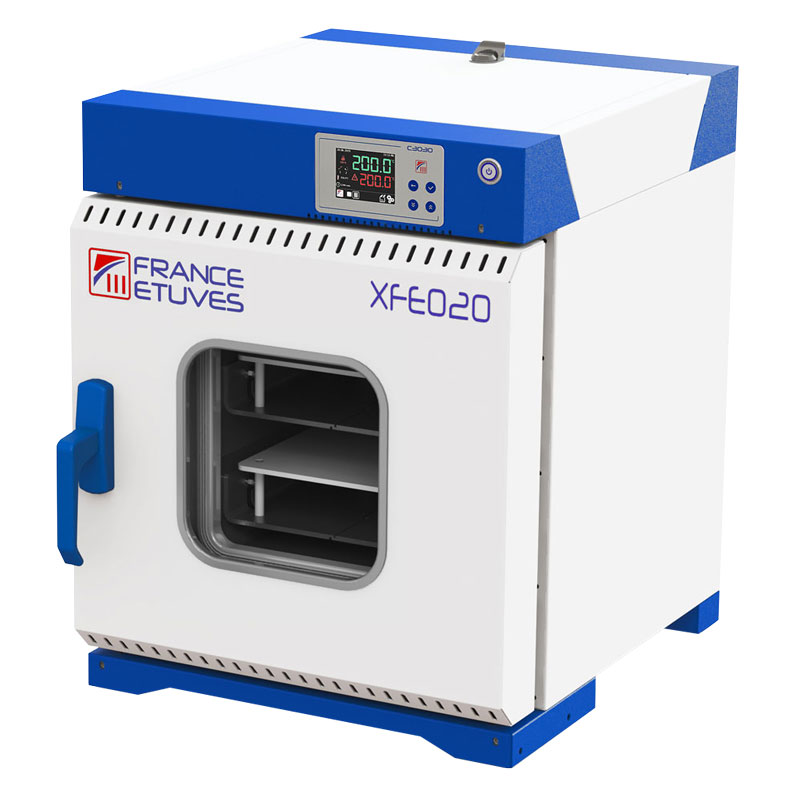

A solid construction for lasting performance.

Exterior made of steel coated with blue and white epoxy paints The inner casing is made of corrosion resistant strong thick stainless steel. THICK INSULATION No contact between the inner and outer casings for no thermal bridge. Insulation is made of asbestos-free glass wool : low surface temperature, low electrical consumption, a rapid rise in temperature. DOOR WITH VIEWING WINDOW The door is equipped with a thick safety glass. SEALING A silicone gasket provides the seal of the door. Closing the door at 2 points. EASY CLEANING The rounded corners of the inner casing make easier cleaning operations ; the racks and the seal are easy-to-remove.

An efficient heating.

Heating is ensured by heating elements located on outer faces of the inner casing for the best homogeneity. The temperature sensor is located inside the oven.

Easy temperature controls.

Vacuum ovens XFE feature a DN16KF passage with a silicone plug. It is possible to introduce sensors for temperature measurements inside the oven.

An easy connectionof your vacuum pump.

Teats allow the pumping of air and vacuum breaking.

Vacuum control

The vacuum level is controlled by the C3030 regulator as soon as the user modifies the vacuum setpoint. The vacuum pump power on/off is automatic. Setting the vacuum setpoint to 0 mbar means a permanent pumping. A "vacuum break" button allows the automatic rise to atmospheric pressure without modifying the vacuum setpoint.

The C3030 temperature profiler

The FRANCE-ETUVES C3030 temperature controller is very accurate and particularly reliable. Measurement by PT100 or TCJ probe. Electronic PID temperature controller. Accuracy: 0.1°C. Color display, excellent visibility of temperatures. Functions : display of setpoint and measured temperature display (in percentage) of the heating power used date and time display vacuum level display Possibility of making 1 program with 8 steps: 4 programmable temperature ramps (°C/min) and 4 heating timer (max 99h59min) delayed start repeat loop monitoring of your current program (step and remaining time) pause or stop the program end of cycle buzzer several settings of the protection thermostat (TWW or TWB modes) PID adjustment possibility of adding a temperature correction at 2 distinct temperatures (offsets) automatic fault diagnosis. Display of faults RS485 modbus multipoint communication: allows to control several ovens on the same network

Protections for your oven and your products.

Heating and pumping, automatic stop when the door is opened . This function can be deactivated in the parameters of the C3030. The ovens are equipped with an electronic thermostat with 2 modes (TWW or TWB) according to DIN 12 880. In TWW mode, the overheating protection thermostat behaves like an electronic thermostat with automatic reset (protection class 3.1). It measures the temperature in the volume, and control the temperature in the event of failure of the temperature controller. It stops heating until the temperature has dropped below the value of its setting. In TWB mode, the overheating protection thermostat behaves like an electronic thermostat with manual reset (protection class 2.0). When the measured temperature exceeds the set value, the heating is switched off. It is only available again if the thermostat is manually reset. Setpoint Deviation Temperature (SDT) The SDT system is a mechanism for monitoring the set temperature within a set tolerance zone. This is a temperature tracking alarm. With visual and audible alarm. Note : It is possible to control the oven with a computer through a RS485 connection and Modbus protocol.

Loading trays

Vacuum ovens XFE are provided with 1 aluminum tray. Each tray can hold up to 30 kg distributed. The racks are easily removable for easy cleaning.

| Model | XFE020 |

|---|---|

| Chamber volume: | 20 litres |

| Performances : | |

|---|---|

| Standard maximum temperature : | 200 °C |

| Optional maximum temperature : | 0 °C |

| Dimensions : | |

|---|---|

| Chamber volume: | 20 litres |

| Interior Dimensions (L x P x H) : | 250 x 320 x 250 mm |

| Exterior Dimensions (L x P x H) : | 480 x 636 x 628 mm |

| Partials product models shleves | |

|---|---|

| Shelves quantity : | 1 delivered / 4 maximum |

| Shelves dimensions : | 240 x 280 mm |

| Max Load per Shelf / Total : | 20 / 60 kg |

| Power & Divers : | |

|---|---|

| Electrical Supply : | 230V ~1P 50Hz 16A |

| Standard power 200 °C : | 800 Watts |

| Number of door(s) : | simple |

| Weight : | 60 kg |

| Model | XFE050 |

|---|---|

| Chamber volume: | 50 litres |

| Performances : | |

|---|---|

| Standard maximum temperature : | 200 °C |

| Optional maximum temperature : | 0 °C |

| Dimensions : | |

|---|---|

| Chamber volume: | 50 litres |

| Interior Dimensions (L x P x H) : | 320 x 500 x 320 mm |

| Exterior Dimensions (L x P x H) : | 550 x 816 x 698 mm |

| Partials product models shleves | |

|---|---|

| Shelves quantity : | 1 delivered / 6 maximum |

| Shelves dimensions : | 310 x 460 mm |

| Max Load per Shelf / Total : | 20 / 80 kg |

| Power & Divers : | |

|---|---|

| Electrical Supply : | 230V ~1P 50Hz 16A |

| Standard power 200 °C : | 1200 Watts |

| Number of door(s) : | simple |

| Weight : | 85 kg |

| Model | XFE120 |

|---|---|

| Chamber volume: | 110 litres |

| Performances : | |

|---|---|

| Standard maximum temperature : | 200 °C |

| Optional maximum temperature : | 0 °C |

| Dimensions : | |

|---|---|

| Chamber volume: | 110 litres |

| Interior Dimensions (L x P x H) : | 470 x 500 x 470 mm |

| Exterior Dimensions (L x P x H) : | 812 x 882 x 908 mm |

| Partials product models shleves | |

|---|---|

| Shelves quantity : | 1 delivered / 4 maximum |

| Shelves dimensions : | 445 x 460 mm |

| Max Load per Shelf / Total : | 20 / 120 kg |

| Power & Divers : | |

|---|---|

| Electrical Supply : | 230V ~1P 50Hz 16A |

| Standard power 200 °C : | 2400 Watts |

| Number of door(s) : | Simple |

| Weight : | 205 kg |

| Range XFE | XFE020 | XFE050 | XFE120 | |

|---|---|---|---|---|

|

|

|

| Performances | ||||

|---|---|---|---|---|

| Temperature range : | Ambient temperature + 20 °C à 200 °C | |||

| Standard maximum temperature : | 200 °C | |||

| Chamber dimensions | ||||

|---|---|---|---|---|

| Chamber volume: | dm3 | 20 | 50 | 110 |

| Width : | mm | 250 | 320 | 470 |

| Depth : | mm | 320 | 500 | 500 |

| Height : | mm | 250 | 320 | 470 |

| Exterior Dimensions | ||||

|---|---|---|---|---|

| Exterior Chamber Volume : | m3 | 0.19 | 0.31 | 0.65 |

| Width : | mm | 480 | 550 | 812 |

| Depth : | mm | 636 | 816 | 882 |

| Height : | mm | 628 | 698 | 908 |

| Shelves: | ||||

|---|---|---|---|---|

| Delivered / Maximum : | 1 / 4 | 1 / 6 | 1 / 4 | |

| Dimensions L / P : | mm | 240 x 280 | 310 x 460 | 445 x 460 |

| Maximum weight / Total : | kg | 20 / 60 | 20 / 80 | 20 / 120 |

| Other informations | ||||

|---|---|---|---|---|

| Number of door(s) : | simple | simple | Simple | |

| Window L / l (option) | mm | 212x212 | 280x280 | 454x454 |

| Weight : | kg | 60 | 85 | 205 |

| Electrical data | ||||

|---|---|---|---|---|

| Standard power 200 °C : | Watts | 800 | 1200 | 2400 |

| Electrical Supply : | volts | 230V ~1P 50Hz 16A | 230V ~1P 50Hz 16A | 230V ~1P 50Hz 16A |

| Reference | Image | Description |

|---|---|---|

| AG9013 |  |

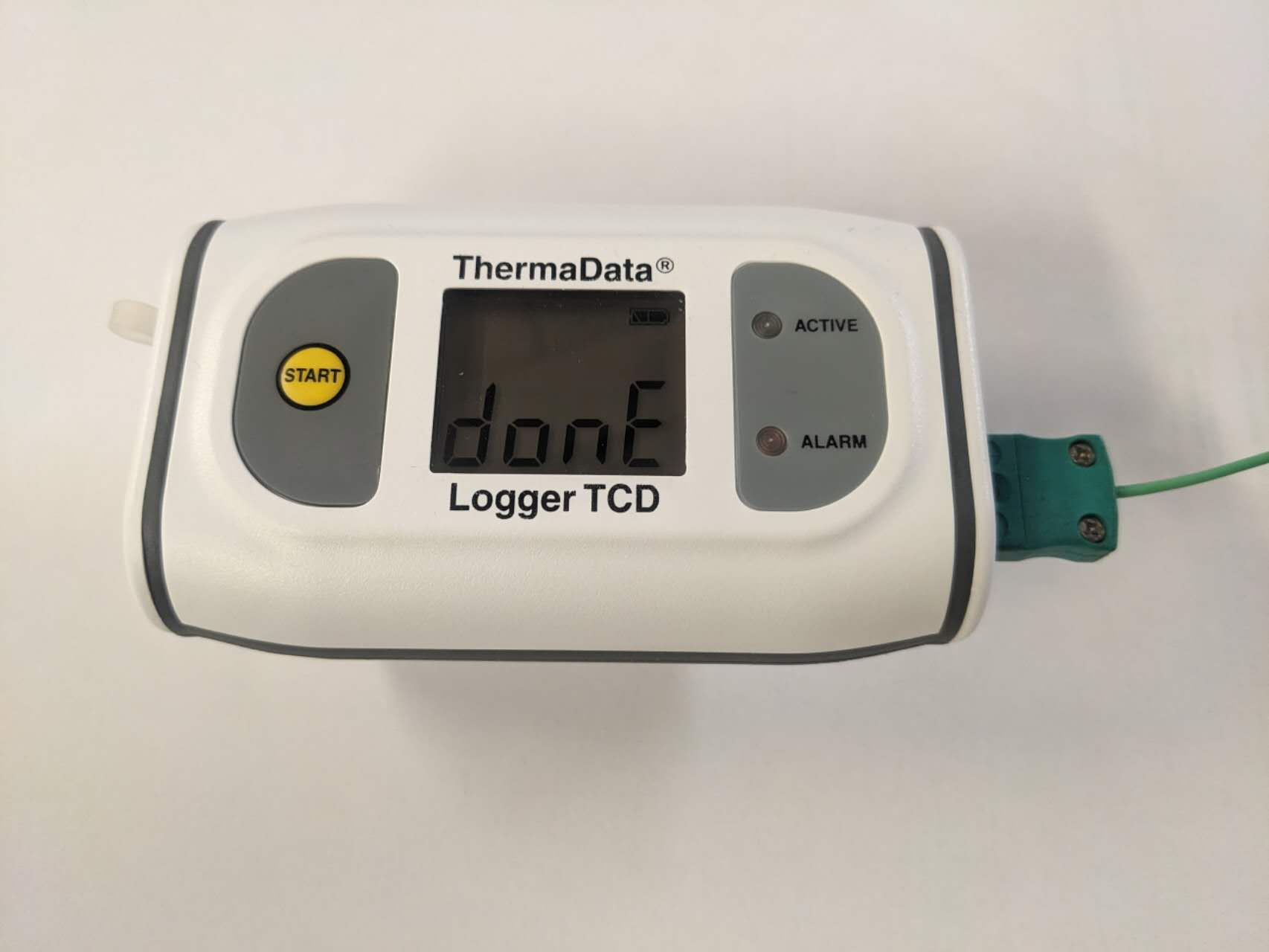

Data logger with 2 channels (software included) Saves the temperatures measured by 2 mobile sensors. Record temperatures measured by 2 mobile sensors. Box with magnetic fixing<br> Dimensions : 93.2 x 65.2 x 30.5 mm Weight: 115 g<br> Display : LCD screen 2 lines | ABS IP54<br> Communication PC : 1 micro-USB Power supply by battery AA lithium 3.6V<br> Tc entries : female connector micro-USB, thermocouples (K, J, T, N, S)<br> Recording from every 1s to 24h Autonomy: 4 years (for 1 measure every 15 monutes) Software and cable included |

| AG9014 |  |

Portable paperless recorder with graphical screen 4 channels Color graphical display for real monitoring of temperature changes. With USB and RJ45 plugs, and 4 connectors for mobile sensors. |

| AG9018 |  |

Vacuum kit up to 1 mbar (oil bath pump) Oil sealed vacuum pump with 1 m flexible hose and exhaust filter |

| AG9024 |  |

Vacuum kit 10 mbar (diaphragm pump) Diaphragm vacuum pump with flexible hose |

| AG9025 |  |

Subframe with castors Elevates the oven for a better loading comfort. Safety glass at the front. Clever storage of the vacuum pump inside. 4 castors, two with brakes. |

| AG9028 |  |

Thermocouple J probe Stainless steel. Length of 2m. With plug and shutter to be placed in passage DN16. |

| AG9029 |  |

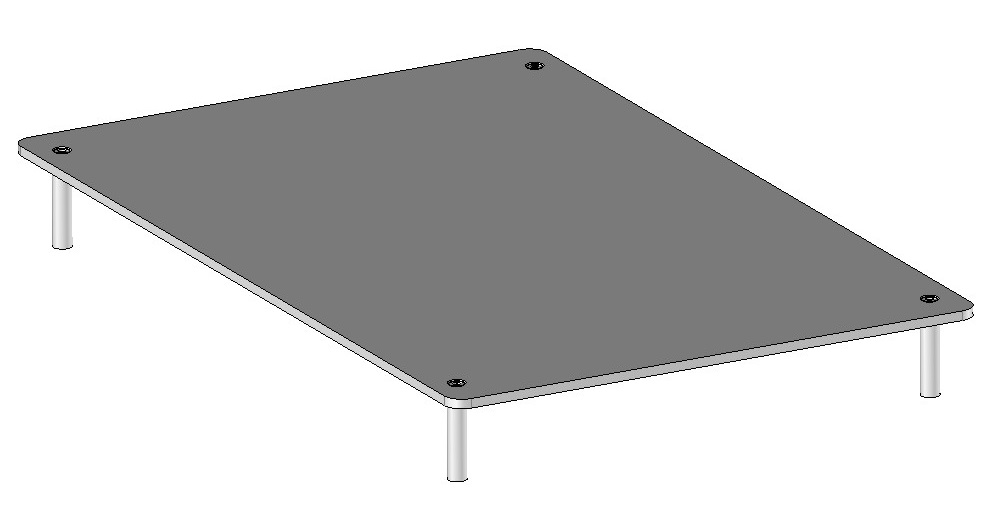

Subframe with feet Elevates the oven for a better loading comfort. Safety glass at the front. Clever storage of the vacuum pump inside. Height adjustable feet. |

| AG9037 |  |

2 probes DN16KF adaptor Airtight adaptor supplied with centering ring and clamp. To be placed on a DN16 KF flange to introduce up to 2 probes inside an oven (probes not included). |

| AG9038 |  |

4 probes DN16KF adaptor Airtight adaptor supplied with centering ring and clamp. To be placed on a DN16 KF flange to introduce up to 4 probes inside an oven (probes not included). |

| AG9039 |  |

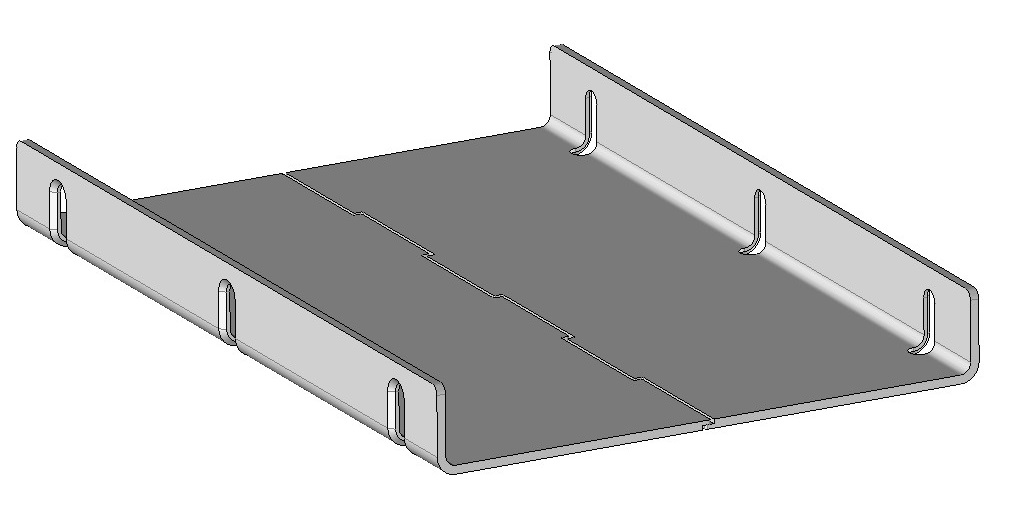

Aluminium thermally conductive tray Main tray to fasten on the walls of the tank. Heat transfer improved by contact in addition to radiation. |

| AG9040 |  |

Aluminium intermediary tray Movable and stackable tray to place on the main thermally conductive trays |