France Etuves

H632

Données techniques :

- Domaine d'activité : Pharmacie

- Volume de la chambre : 343 litres

- Température max: 50 °C

Etuve conçue sur-mesure pour le stockage de flacons fermés d???éthanol à 40°C.

- Données techniques :

- Volume utile : 343 L

- Dimensions intérieures LxPxH : 700x700x700 mm

- Puissance de chauffage : 3000 W

- Température mini / maxi : température ambiante + 15°C / 50°C

- Bruit aérien émis : inférieur à 70 dB

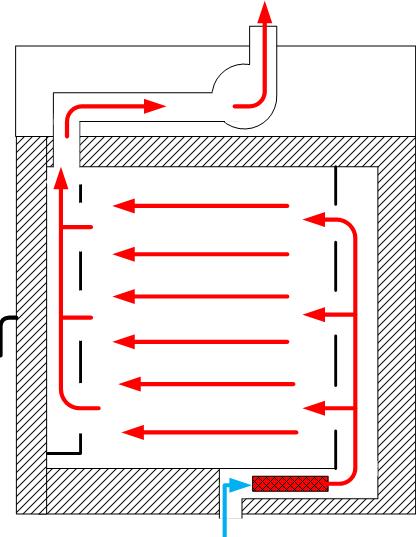

Un extracteur ATEX assure un renouvellement d???air permanent. Le débit minimum de renouvellement d???air requis est 150m3/h ; un variateur ajuste le débit. Le débit est vérifié par un pressostat dans la gaine de renouvellement d???air ?? 100 mm, situé sur le dessus de l???étuve. L???évacuation de l???air chaud de l???étuve est effectuée par un conduit indépendant de tout autre circuit d???extraction. La large entrée d???air, située sous l???étuve, est grillagée afin d???éviter que des impuretés n???entrent dans l???étuve.

La régulation en température est assurée par un régulateur-enregistreur permettant de réguler l???étuve à une température constante et d???enregistrer les températures mesurées.

Un connecteur RJ45 permet de communiquer à distance avec le régulateur-enregistreur. Un port USB permet de récupérer les données enregistrées.

Une sécurité électronique assure la régulation en cas de défaillance du régulateur principal et permet de couper le chauffage en cas de surchauffe.

Les sondes de régulation et de sécurité sont des sondes PT100 ATEX.

Le chauffage est coupé au démarrage de l???étuve, en cas d???apparition de défaut et d???ouverture de porte. Un bouton de réarmement permet d???activer le chauffage en cas de démarrage d???un cycle de température, après avoir résolu un défaut ou avoir refermé la porte.

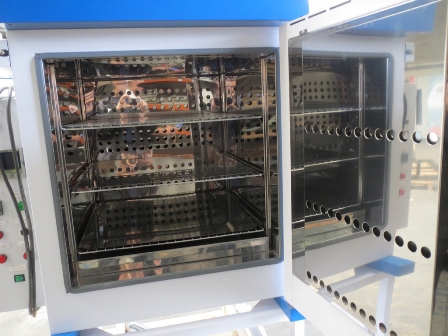

L???intérieur de l???étuve est en acier inoxydable 430.

L???étuve est fixée sur un socle de rehausse muni de pieds réglables en hauteur afin de mettre l???étuve de niveau.

Un passage cloison ?? 20 mm est centré sur la face latérale droite. Il est fourni avec un bouchon. Il permet de passer des câbles, des sondes de contrôle de température???

L???étuve est fournie avec des clayettes de chargement pouvant supporter jusqu???à 30kg répartis chacune. Les clayettes reposent sur des supports anti-basculement pour un chargement et un déchargement facilités. Un bac de rétention en inox de 20L doit être déposé sur la sole afin de récupérer les condensats.