Why France Etuves?

Laboratories & Industries

Any type of application

Experience & expertise

Innovative solutions

Our ingenuity defying the ordinary, our innovative solutions open new promising horizons.

Une réponse personnalisée à chaque client

Avec des décennies d'expérience dans l'industrie, nous nous positionnons en tant que leader incontesté dans notre domaine.

Chez France Etuves, nous offrons des solutions à la pointe de la technologie et nous répondons aux besoins les plus complexes de nos clients. Que vous soyez à la recherche de machines industrielles de pointe, de solutions d'automatisation avancées ou de services de consultation spécialisés, nous sommes là pour vous accompagner tout au long de votre parcours.

Vous bénéficiez d'une collaboration avec un partenaire de confiance, engagé à fournir des résultats à la hauteur de vos attentes et de vos exigences. Votre satisfaction nous permet de tisser des relations durables.

Innovation begins with a conversation.

Contact our specialists now

Innovations that mark progress.

- Field of Activity : Aérospatial

- Chamber Volume : 3.724 m3

- Temperature : 150 °C

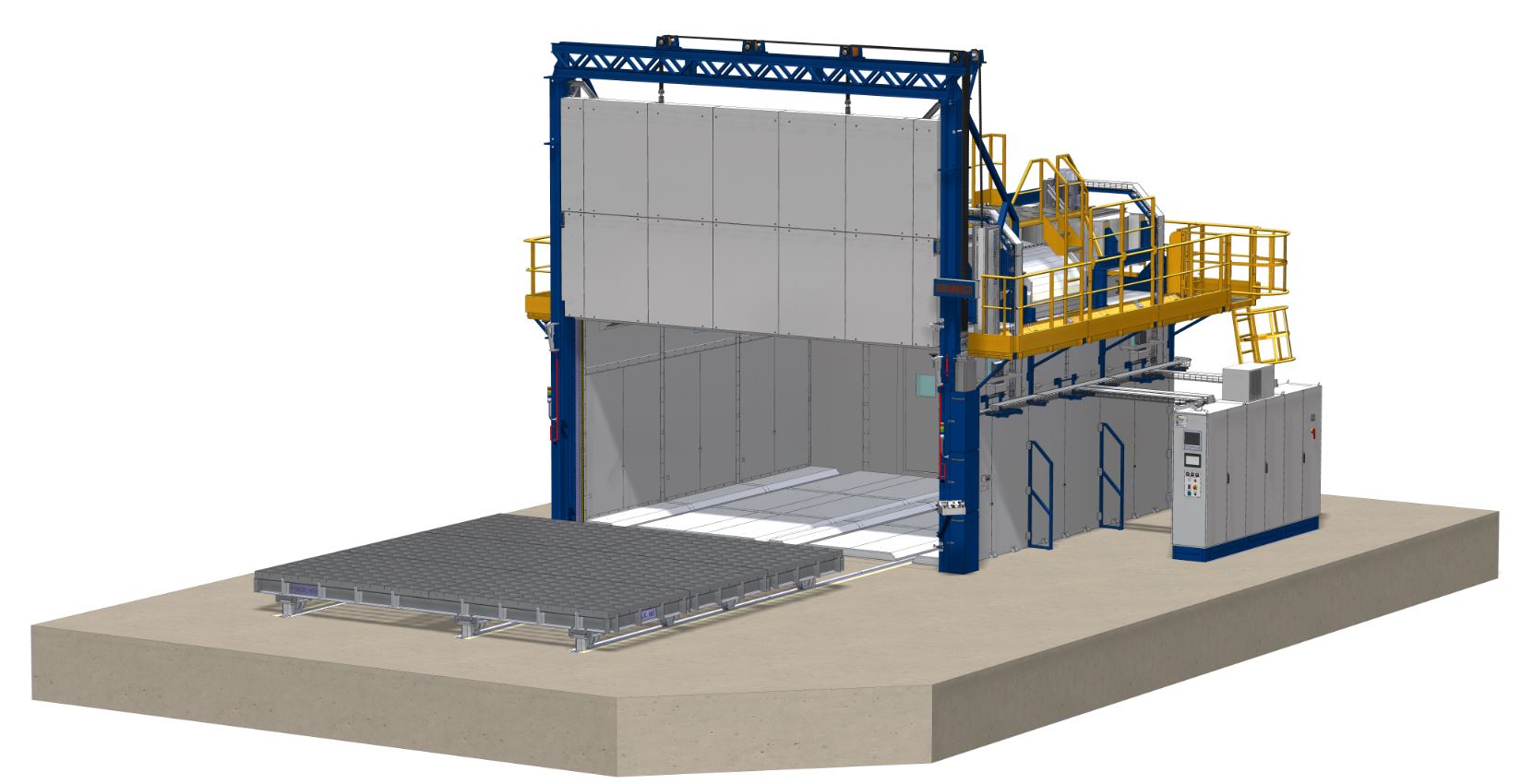

- Field of Activity : Aérospatial

- Chamber Volume : 132 m3

- Temperature : 300 °C

- Field of Activity : Aérospatial

- Chamber Volume : 2.9 m3

- Temperature : 200 °C

They trust us

France Etuve is 20,000 ovens delivered since its establishment and many trusted collaborations forged over the years