Pourquoi France Etuves ?

Laboratoires & Industrie

Tout type d'application

Expérience & expertise

Solutions innovantes

Notre ingéniosité défiant l'ordinaire, nos solutions innovantes ouvrent de nouveaux horizons.

Une réponse personnalisée à chaque client

Avec des décennies d'expérience dans l'industrie, nous nous positionnons en tant que leader incontesté dans notre domaine.

Chez France Etuves, nous offrons des solutions à la pointe de la technologie et nous répondons aux besoins les plus complexes de nos clients. Que vous soyez à la recherche de machines industrielles de pointe, de solutions d'automatisation avancées ou de services de consultation spécialisés, nous sommes là pour vous accompagner tout au long de votre parcours.

Vous bénéficiez d'une collaboration avec un partenaire de confiance, engagé à fournir des résultats à la hauteur de vos attentes et de vos exigences. Votre satisfaction nous permet de tisser des relations durables.

L'innovation commence par une conversation.

Contactez nos spécialistes dès maintenant

Innovations qui marquent le progrès

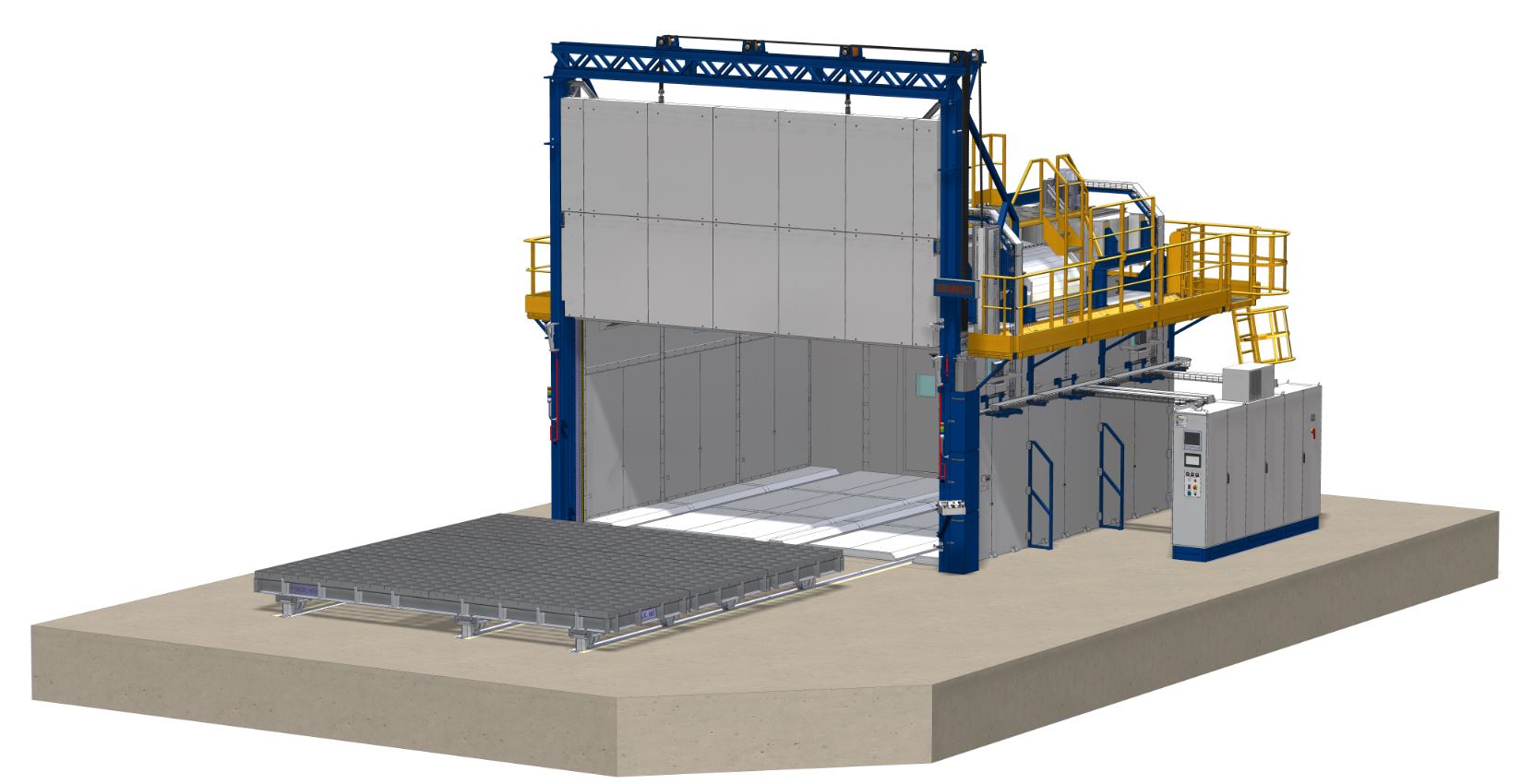

- Domaine d'activité : Aérospatial

- Volume de la chambre : 3.724 m3

- Température : 150 °C

- Domaine d'activité : Aérospatial

- Volume de la chambre : 132 m3

- Température : 300 °C

- Domaine d'activité : Aérospatial

- Volume de la chambre : 2.9 m3

- Température : 200 °C

Ils nous font confiance

France Etuves c’est 20.000 étuves livrées depuis sa création et de nombreuses collaborations de confiance nouées au fil des années